Standart-AW

- Max Operating Pressure : 16bar (Screw thread type) / 10bar (Flange type)

- Differential pressure : 0.07 bar

- Volume flow rate : 1~400 NmVmin

- Operating Temp. Range : 1.5°C ~ 80°C

- Service life of element : 6000 hours

PRODUCT DESCRIPTION

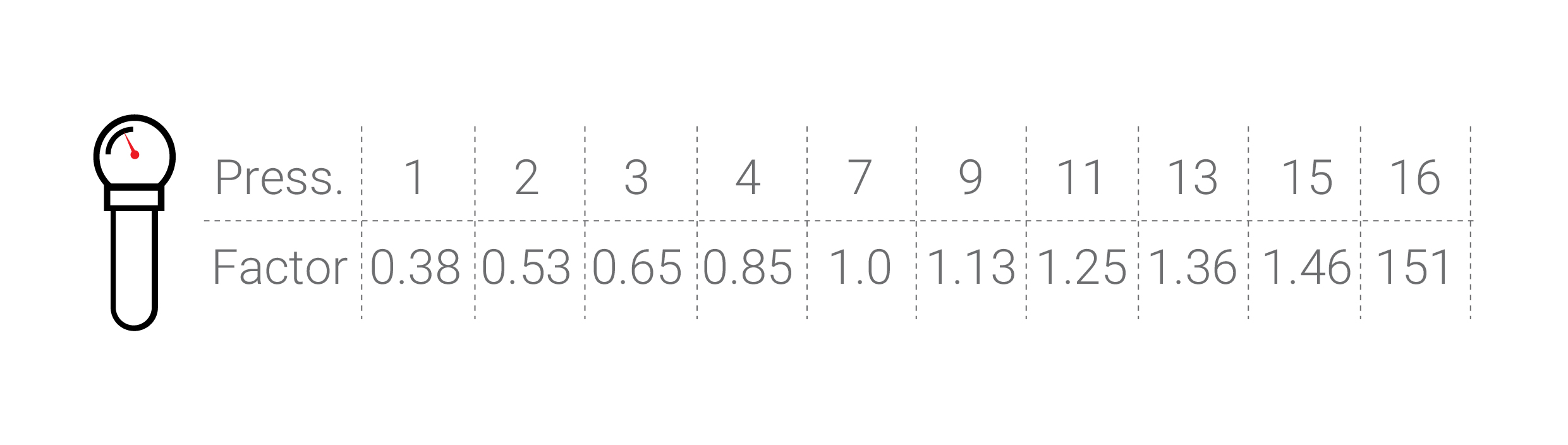

- Inlet Pressure (bar)

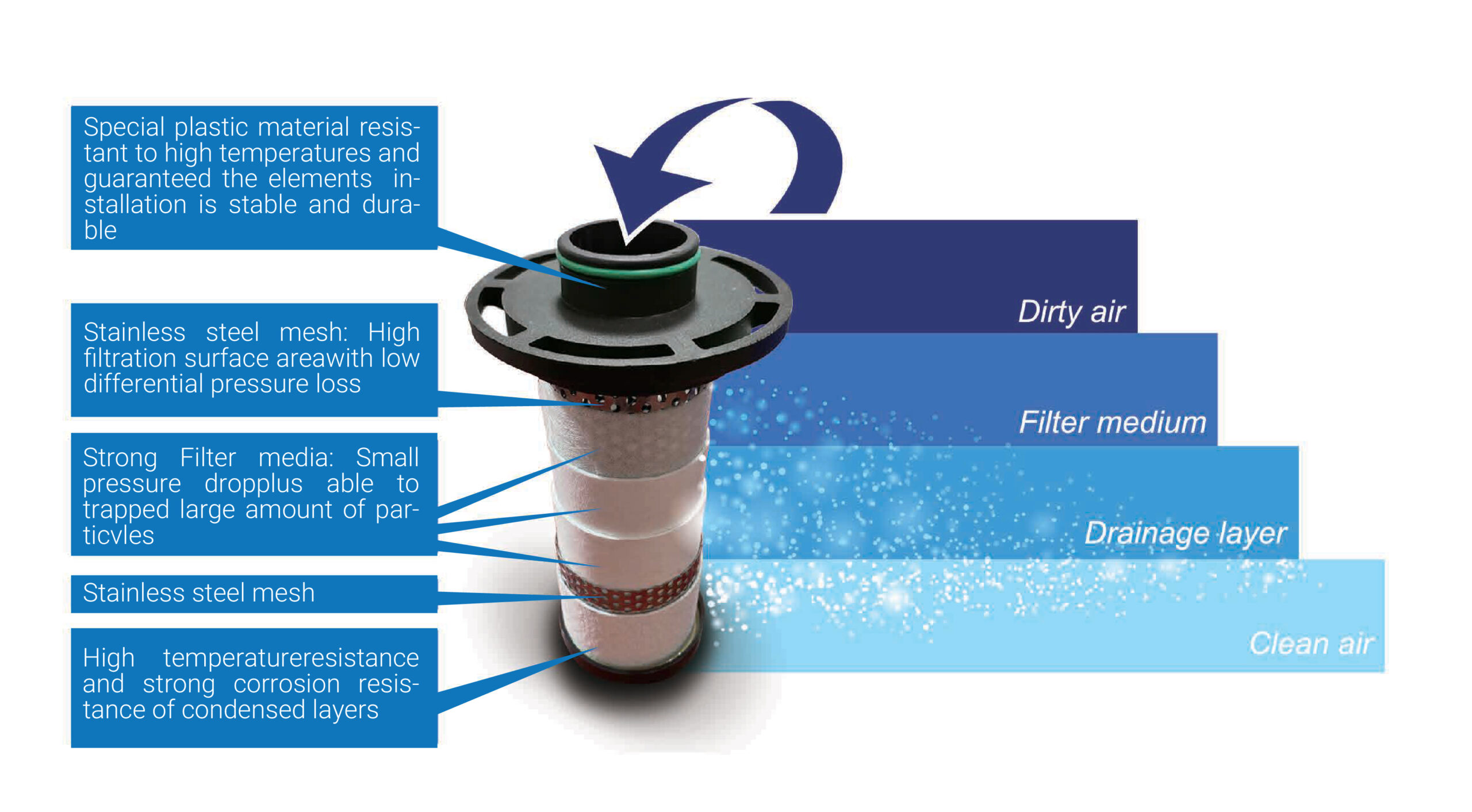

Airbone particles, water vapour, microbes, and chemical gases enter compressors. After compression has taken place these contaminants become concerated and more destructive. Compressed air quality is essential to all modern production facilities. Compressed air filter, often referred to as line filters, are used to remove these contaminates from compressed air. Clean and dry air protects the compressed air system, reduces maintenanace costs and increases finished product quality

- Filter housing internal with anti-corrotion treatment

- Optional accssesories : Differential pressure indicator / sight glass / inner drainer / External auto drainer

Separator Filter (C)

For bulk liquiud removal plus a 3 micron coalescer (5ppm 2/2)

maximum remaining oil content

Two-stage filtration

• First stahe: two stainless steel orifice tubes provide 10 micron mechanical separation

• Second stage: in-depth fiber media captures solid and liquid particles to 3 micron

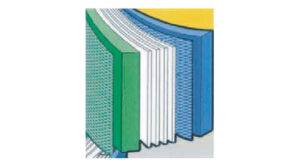

High Efficiency Oil Removal Filter (A)

For coalescing fine water and oil aerosols; removes solid particles to 0.01 micron (0.01 ppm w/w maxim,um remaining oil content

Corrosion Resistant Inner And Outer Cores. Two Stage Filtration

• First stahe: multiple layers of bonded, blended fiber media for fine coalescene

• Second stage: multiple layers of bonded, blended fiber media for fine coalescence

Outer Coated, closed cell foam sleeve

Oilvapor Removal Filter (H)

For removal of oil and hydrocarbon vapors normally absorbable by activated carbon; removes solid particles to 0.01 micron (0.003 ppm w/w maximum remaining oil content)

(0.003 ppm w/w maximum remaining oil content)

Two-stage filtration

• First stahe: a stabilized bed of finely divided carbon particles removes the majority of the oil vapor

• Second stage: multiple layers of fiber media with bonded micro fine carbon particles removes the remaining oil vapor Multiple layers of fine the media prevent particie migration Outer coated, closed cell foam sleeve prevents fiber migration Designed for 100 hour life at rated conditions.

Air Line Filter (T)

For removal of liquid water and oil; removes solid particles to i micron (1.0 ppm w/w maximum remaining oil content)

Corrosion resistant inner and outer cores. Two-stage filtration

• First stahe: captures larger particles wit alternate layers of fiber media and media screen

• Second stage: coalesces aerosols and captures solid particles with multiple layers of epoxy bonded, blended fiber media

Ultra High Efficiency Oil Removal Filter (AA)

For coalescing ultra-fine oil aerosols; removes solid particles to 0.01 micron (0.001 ppm w/w maximum remaining oil content)

Corrosion resistant inner and outer cores. Two-stage filtration

• First stahe: coated, closed cell foam sleeve acts as pre-filter and flow dispenser

• Second stage: multiple layers of matrix blended fiber media for ultra-fine coalescence

Outer coated, closed cell foam sleeve

| Model | Capacity Nm3/min | Air Connections | L | Dimensions(mm) W | H | Weight KG |

| AWC. T. A. AA. H-001 | 1.4 | G1” | 102 | 92 | 265 | 1.4 |

| AWC. T. A. AA. H-002 | 2.4 | G1” | 117 | 96 | 293 | 1.9 |

| AWC. T. A. AA. H-003 | 3.8 | G1”.5” | 133 | 110 | 330 | 3 |

| AWC. T. A. AA. H-006 | 6.5 | G1”.5” | 133 | 110 | 428 | 3.4 |

| AWC. T. A. AA. H-008 | 8.5 | G1”.5” | 133 | 110 | 428 | 4 |

| AWC. T. A. AA. H-010 | 10.7 | G2” | 195 | 129 | 555 | 5.7 |

| AWC. T. A. AA. H-013 | 13.5 | G2” | 195 | 129 | 555 | 6 |

| AWC. T. A. AA. H-015 | 18 | G2” | 205 | 152 | 810 | 12 |

| AWC. T. A. AA. H-015 | 18 | DN65 | 310 | 152 | 810 | 25 |

| AWC. T. A. AA. H-020 | 22 | G2.5” | 205 | 152 | 810 | 13 |

| AWC. T. A. AA. H-020 | 25 | DN80 | 370 | 152 | 810 | 44 |

| AWC. T. A. AA. H-025 | 28 | DN80 | 370 | 133 | 1360 | 52 |

| AWC. T. A. AA. H-030 | 35 | DN100 | 450 | 219 | 1164 | 65 |

| AWC. T. A. AA. H-040 | 45 | DN100 | 450 | 219 | 1164 | 68 |

| AWC. T. A. AA. H-050 | 55 | DN125 | 513 | 273 | 1218 | 96 |

| AWC. T. A. AA. H-060 | 65 | DN125 | 513 | 273 | 1218 | 98 |