HPS Series

- Air Cooled

- Twin Screw Single Stage Air End – August- Brand

- 5 Year Rotor Warranty

- 45,000-50,000 Working Hours Engineered Lifetime

- Skf Explorer Bearings (Mainly)

- Energy Saving Micro Control System, Fully Automated Operation

- Easy Maintenance

PRODUCT DESCRIPTION

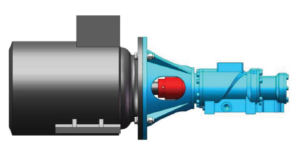

The Latest Generation of High Efficient Air End

- Self-developed tooth shape, large diameter rotor,

low speed, long life

low speed, long life - High precision rotor grinder and three coordinate

measuring instrument to ensure the precision

machining of the air end - Finite element analysis of reliable key parts to

optimize the quality of each part

The latest development of efficient XA series single-stage rotor

- Protection grade IP55, insulation grade F, suitable for

bad working conditions

bad working conditions - Without gear box design, the motor is directly connected

with the male rotor of the air end, High transmission

efficiency - High balance preciwion, high speed running smoothly

- Operation interface is simple, English and Chinese switch, Fully automatic operation,easy to operation

- Integrated maintenance reminder, fault diagnosis to achieve unattended operation computer remote

monitoring, start - stop

The air end is connected with the motor through the socket, coupling drive, split design, air end maintenance

only need to disassemble the air end, motor maintenance only need to disassemble motor, do not each other,

easy maintenanace.

Products are reliable, stable, cost-effective, less quick-wear part, low maintenance costs, beautiful overall

appearance

- Air Cooled

- Twin Screw Single Stage Air End – August- Brand

- 5 Year Rotor Warranty

- 45,000-50,000 Working Hours Engineered Lifetime

- Skf Explorer Bearings (Mainly)

- Energy Saving Micro Control System, Fully Automated Operation

- Easy Maintenance

- Low-Noise Operation, Closed Cabinet Structure, Noise Reducing Dumping Mats Made Of Fire-Retardant Materials

- Drive Drive

- Drawing For Reference Only

- Efficient, Safe And Reliable Fully Enclosed Motor Drive (Ip54, F Class / Ip55 Optional)

- Energy Saving Air End 5:6 Helix

- Networkable Link Between Compressors / Grouping With On-Line, Remote Monitoring And Dsc Network Functions

- High Precision Heavy Duty Intake Filter 1Μm, 99.9% Efficiency

- Optimized Oil Separation System Residual Oil Rate 1-3Mg/M3

- Low Speed Air End Operation

- Powerful Low Noise Exhaust Fan / On Top Exhaust

- Automatic Control Of Functions / Maintenance Indicator

- English Language Display, Easy Operation, Running Status At A Glance, Runningreal-Time Monitoring Data

- Pressure And Temperature Control And Protection

- Start Up Protection ( Current Spike Free)

- English Language Display / English Language Manual

|

Model |

Motor Power (KW/HP) | Discharge Pressure (MPa) | Free Air Delivery (m³/min) | Weight (kg) | Noise dB(A)±3 | Overall Dimension (L×W×H mm) | Air Supply Out |

| HPS11/16 | 11/15 | 1.6 | 0.4-1.0 | 380 | 67 | 1298×754×1082 | 1〞 |

| HPS15/16 | 15/20 | 1.6 | 0.52-1.3 | 380 | 67 | 1298×754×1082 | 1〞 |

| HPS22/16 | 22/30 | 1.6 | 0.92-2.3 | 450 | 72 | 1354×854×1182 | 1-1/4〞 |

| HPS37/16 | 37/50 | 1.6 | 1.68-4.2 | 990 | 74 | 1533×1003×1345 | 1-1/2〞 |